← Expand Solutions

EXPAND SYSTEMS

FINISHING SOLUTIONS

Expand Systems Finishing

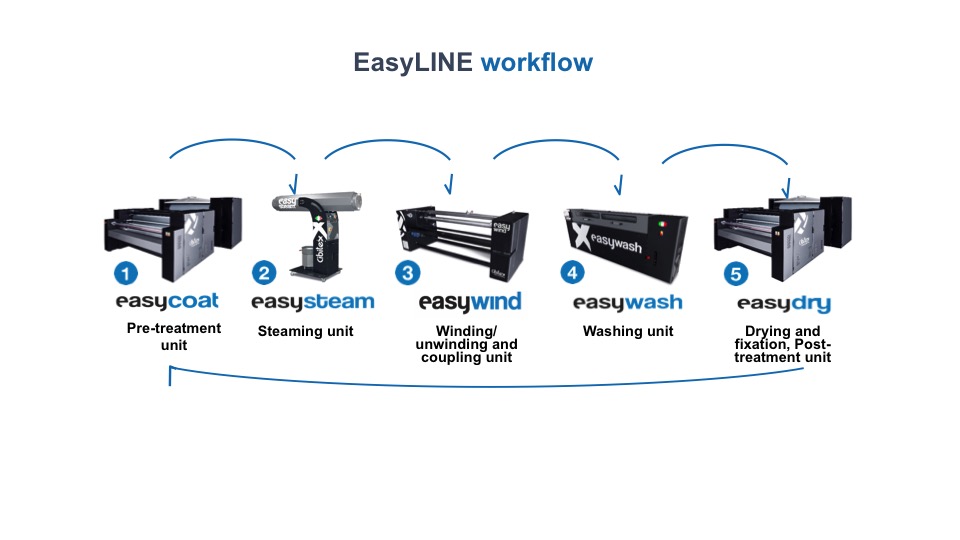

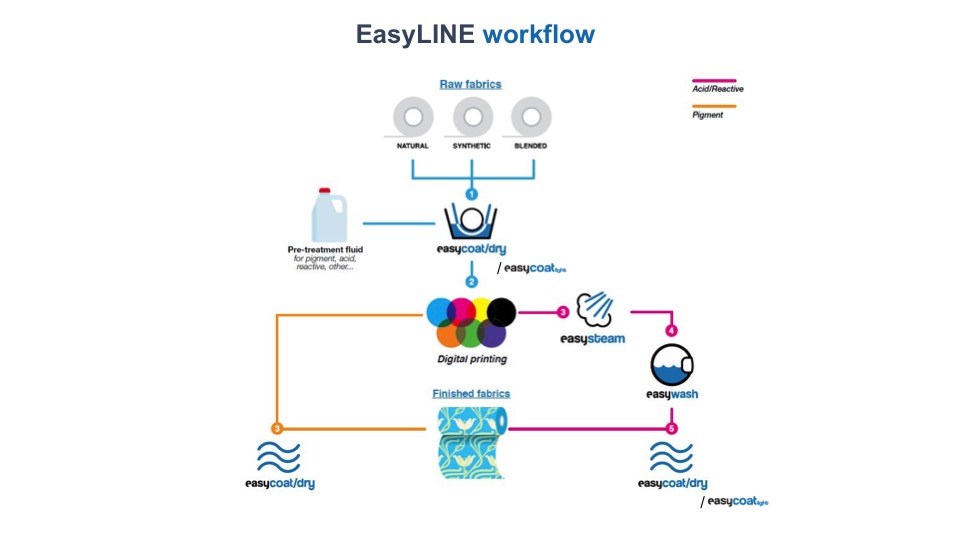

Multifunctional pre-treatment/drying/fixation/post-treatment/curing unit for digital textile printing

Stand-alone unit and with an open source system, can be combined together with the most efficient printers on the market. Developed for Pre-treatment for pigment, acid, reactive printing; can be useful also for drying after washing process and for endless types of finishing (water repellent, antibacterial, anti UV, etc.). It’s the most versatile unit on the market.

FEATURES

- Machine size 138in x 216in x 75in

- Productivity Up to 6 lm/min

- Temperature Max 392°F

- Power installed 220V or 480V – 3 Phase

FEATURES

- Machine size 40in x 30in x 108in

- Capacity of fabric reels Up to 50 mt fabric per cycle

- Temperature Max 215°C

- Power installed 220V or 480V – 3 Phase

On-demand steaming unit for small and medium batches of printed fabrics for digital textile printing

This unit can be combined together with entry level digital textile printers to steam small/medium batches of a wide range of fabrics printed with reactive/acid inks. It stands out for its ease of use and easy integration even in an existing workflow.

Professional washing unit for digital textile printing

This washing unit was created to overcome the criticality imposed by conventional washing systems that usually require large amounts of water, energy and space. Thanks to its extraordinary compactness and versatility, easyWASH can operates with reduced water consumption* and minimum energy requirements. The exclusive motionless technology, allows to wash fabric rolls of up to 200 meters in less than an hour.

*ECO version available.

FEATURES

- Machine size 129in x 28in x 53in

20in x 20in x 35in(recycling unit) - Productivity Up to 200 m of fabric per cycle

- Water consumption

Max 800 liters/h

Max 500 liters/h (ECO version - Power installed 220V or 480V – 3 Phase

FEATURES

- Machine size 152in x 47in x 51in

- Winding/unwinding speed up to 20 lm/m

- Power installed 220V or 480V – 3 Phase

Winding/unwinding and coupling unit for digital textile printing

This unit is very helpful in combination with steamer and washer, because it really can quicken the operations between each stage. Thanks to the high speed and automation system, it can couple the fabric with the polyester mesh for steaming*, uncouple it and, in the same operation, prepare the washing pipe in a few minutes.

*this operation can be done directly at the exit of the printer